Load Cell Guide: Difference between revisions

| Line 140: | Line 140: | ||

===Load Cell Accuracy=== | ===Load Cell Accuracy=== | ||

Load cells sold by Phidgets Inc. are categorized into different types, as mentioned above, as well as different accuracy classes. An overview of general accuracy is available in the table below | Load cells sold by Phidgets Inc. are categorized into different types, as mentioned above, as well as different accuracy classes. An overview of general accuracy is available in the table below: | ||

{| style="margin:auto;width:85%;" | {| style="margin:auto;width:85%;" | ||

Latest revision as of 17:29, 7 December 2023

Introduction

Do you need to build a system that can measure weight? Using load cells and load cell interfaces from Phidgets Inc. makes this extremely simple! Watch the video below, or keep reading for more information.

What Is a Load Cell?

A load cell is a device that converts mechanical force into a signal that can be measured.

There are different types of load cells, such as pneumatic, hydraulic, capacitive, etc. but strain gauge load cells are the most common.

Strain Gauge Load Cells

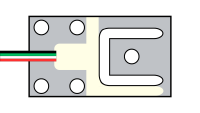

Strain gauge load cells use a small resistive sensor called a strain gauge to convert mechanical force into an electrical signal.

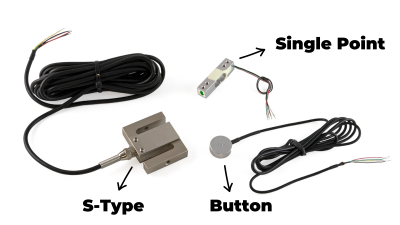

There are many different types of strain gauge load cells (some can be seen in the image above). Each type of load cell is designed for a particular application, however, they all have the same basic components:

| An inflexible frame or body, generally made of aluminum or a steel alloy. | |

| One or more strain gauges. | |

| Wires for power, ground, and signals. |

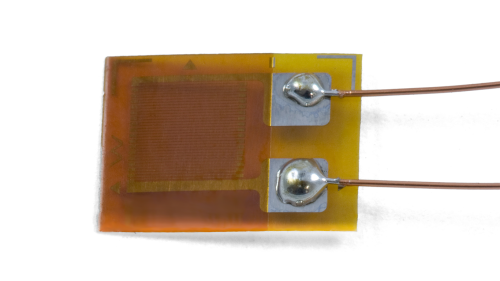

Strain Gauge Basics

A strain gauge consists of a thin metal wire that is arranged in a specific pattern and attached to a flexible, non-conductive backing material.

As the strain gauge experiences tensile or compressive forces, the metal wire deforms which causes the resistance of the strain gauge to change. This change in resistance causes a voltage change which can be measured.

Which Load Cell Should I Use?

There are many different types of strain gauge load cells to choose from. Phidgets Inc. carries the following types and capacities:

| Type | Description | Max Capacity | |

|---|---|---|---|

| Single-Point | Used for small to medium-capacity weighing scales (e.g. kitchen scale). | 50kg |

|

| S-Type | Used to measure tension (e.g. hanging loads), and, less commonly, compressive forces. | 500kg |

|

| Platform | Used for robust multi-point weighing platforms. | 500kg + |

|

| Button | Used for weighing scales, especially where space is limited. | 1000kg |

|

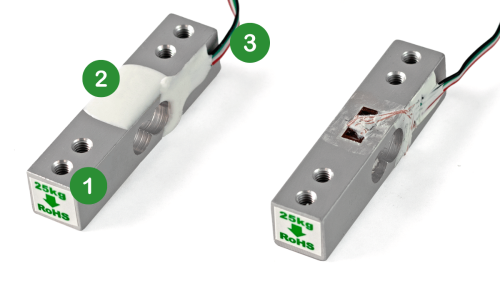

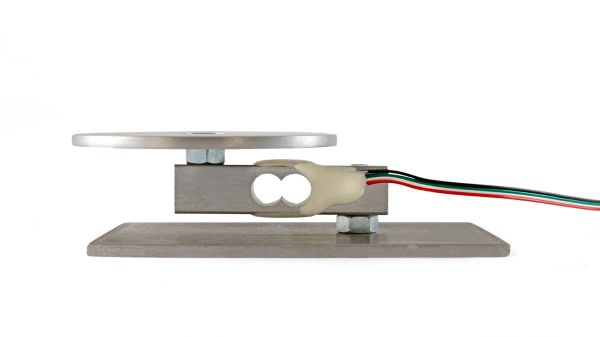

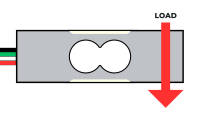

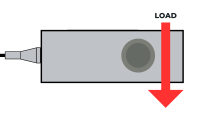

Single-Point Load Cells

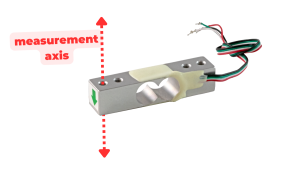

Single-point load cells, sometimes referred to as Platform or Binocular load cells, are easy-to-use load cells that are commonly seen in small weighing scales (e.g. kitchen scales).

Form Factor

These load cells are beam shaped and typically have two circular holes machined out of the middle (hence, 'binocular load cells'). These holes encourage bending along the measurement axis. They also have mounting holes (generally 1-2) at both ends for simple installation.

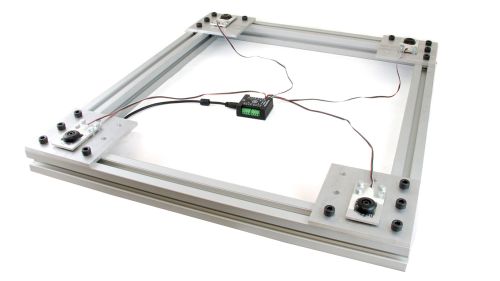

Use Cases

Single point load cells are primarily used to create platform scales, like the Weighing Scale Kit. They are ideal for this task because they support off-axis loading. This means that users can place their object anywhere on the surface of the scale and the results will still be accurate.

Installation

Single-point load cells typically have an arrow showing which direction the load should be applied. One end of the load cell is secured to the base of the platform, while the other is secured to the top plate. These load cells cannot be combined to increase weighing capacity.

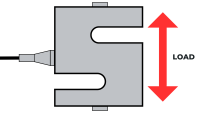

S-Type Load Cells

S-type load cells, sometimes referred to as Z-type or S-beam load cells, are easy-to-use load cells that allow you to measure both tensile and compressive forces.

Form Factor

These load cells are S-shaped, with two mounting holes located at the top and bottom.

Use Cases

S-type load cells are primarily used to measure the weight of suspended loads, the strength/durability of wires, cables, ropes, etc., and any other tensile application. They can also be used in compression, though it is less common.

Installation

S-type load cells are generally used with eye bolts or rod end bearings which provide an easy connection point to the rest of a system.

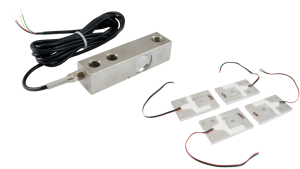

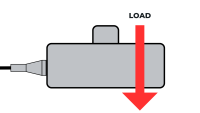

Platform Load Cells

Platform load cells are designed to be used in parallel for multipoint load cell platforms.

Form Factor

Platform load cells from Phidgets Inc. are currently available in two different form factors:

- Shear beam

- Platform (Matched set of 4)

Shear beam load cells are typically beam-shaped with a solid rectangular profile. Our platform load cells are flat with multiple holes machine out of the body.

Use Cases

Platform load cells are used to create durable multipoint weighing platforms that can easily handle large dynamic loads. Examples are bathroom scales and livestock scales.

Installation

Our shear beam load cells typically have an arrow showing which direction the load should be applied. One end of the load cell is secured to the base of the platform or can be placed directly on the ground using the included rubber swivel foot, while the other is secured to the top plate.

Our platform load cells (matched set of 4) have four mounting holes for easy connection onto a frame, and a single mounting hole that is often used with a rubber pad or vibration mount that rests on the ground.

Button Load Cells

Button load cells, sometimes called load buttons, are low-profile load cells that allow you to measure compressive forces.

Form Factor

These load cells are small and cylindrical. They have a small button protruding from the top where mechanical force is intended to be focused. They also have mounting holes (generally 3-4) on the bottom.

Use Cases

Button load cells are primarily used for weighing applications where space is limited. Multiple button load cells can be used together to increase weighing capacity.

Installation

The bottom of the load cell can be easily secured to a base using mounting holes. A top plate can be added, though precise cutouts for the protruding buttons are required.

Load Cell Accuracy

Load cells sold by Phidgets Inc. are categorized into different types, as mentioned above, as well as different accuracy classes. An overview of general accuracy is available in the table below:

| Class | Total Error |

|---|---|

| C4 | 0.020% |

| C3 | 0.025% |

| C2 | 0.031% |

| C1 | 0.053% |

| Consumer | 0.1% |

As shown above, class C4 load cells have less total error, and provide greater performance regarding accuracy, repeatability, and drift.

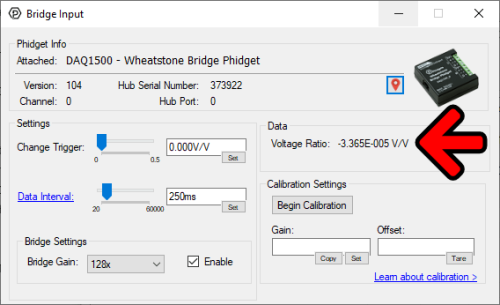

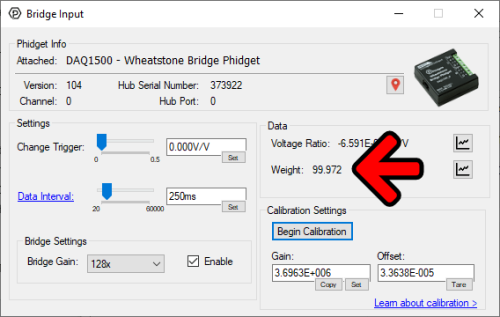

How Do I Get Data From My Load Cell?

The output from a load cell is a very small analog voltage. Amplification is required in order to obtain useful data. Luckily, the load cell interfaces from Phidgets Inc. do this for you and provide a clean, stable digital value to work with.

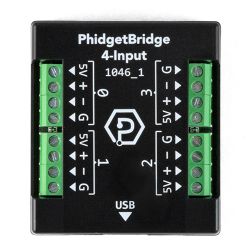

Selecting a Load Cell Interface

Phidgets Inc. offers two load cell interfaces:

|

|

Relevant Specifications

| Wheatstone Bridge Phidget (DAQ1500_0) | PhidgetBridge 4-Input (1046_1) | |

|---|---|---|

| Controlled By | VINT | USB |

| Load Cell Inputs | 2 | 4 |

| Maximum Sample Rate (One Input Used) | 50Hz | 1200Hz |

| Maximum Sample Rate (All Inputs Used) | 10Hz | 125Hz |

| ADC Resolution | 24 bits - 59.9nV/V | 24 bits - 59.9nV/V |

| Avg System Cost | $60USD | $95USD |

Connecting Your Load Cell to Your Load Cell Interface

After selecting a load cell interface, you can easily connect your load cell to it using a 2mm screwdriver.

Be sure to check the datasheet for your specific load cell before connecting.

| Wire Color | Function | Load Cell Interface Port |

|---|---|---|

| Red | VCC | 5V |

| Green | + | + |

| White | - | - |

| Black | GND | G |

How Do I Convert My Load Cell Output To Pounds, Grams, Newtons, etc.

The output from a load cell is normally reported with units of volts per volt (V/V) or milliVolt per volt (mV/V).

In order to convert the units into something more meaningful like grams, pounds, newtons, etc. a simple calibration is required. For more information, visit our load cell calibration guide.