|

Notice: This page contains information for the legacy Phidget21 Library. Phidget21 is out of support. Bugfixes may be considered on a case by case basis. Phidget21 does not support VINT Phidgets, or new USB Phidgets released after 2020. We maintain a selection of legacy devices for sale that are supported in Phidget21. We recommend that new projects be developed against the Phidget22 Library.

|

Solid State Relay Primer

|

|

Introduction

Solid state relays (SSRs) turn on or off the power being supplied to other devices without the need of a physical switch. With relays, you control high-current devices with low-current signals, like a standard DC signal from a Digital Output.

They perform the same job as Mechanical Relays, but have the following advantages:

- SSRs produce less electromagnetic interference during operation, as opposed to mechanical relays, where internal contacts spark when switching.

- The switch contacts of a mechanical relay will eventually wear down from sparking. An SSR will have a longer life because its internals are purely digital. Properly used, they will last for millions of cycles.

- SSRs turn on and off faster than mechanical relays (≈1ms compared to ≈10ms).

- SSRs are less susceptible to physical vibrations than mechanical relays.

- Since the switch inside an SSR isn't a mechanical switch, it does not suffer from contact bounce, and operates silently.

SSRs are more expensive to produce and will dissipate more energy in the form of heat (1-2% of the energy intended to power the load).

How it Works

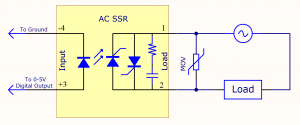

The control inputs are connected internally to an LED, which shines across an air gap to light sensors. The pairing of an LED with light sensors is called an optocoupler, and is a common technique to link two parts of a circuit without direct connection. The light sensor is connected to the transistors which open or close, supplying the relay's load with power.

Basic Use

Controlling an SSR is no more complicated than driving an LED. There are many ways of accomplishing this with Phidgets -

- Link to Digital Output Page, SSR Section

- Link to Digital Output Page 0/16/16, SSR Section

- Link to LED Output Page, SSR Section

The ability of an SSR to switch a load is very similar to a relay or simple switch. In practice however, there is no one SSR perfect for all applications. To choose an SSR for your application, please follow #Choosing an SSR

Safety

Relays can switch high currents and voltages, and standard precautions apply. Make sure you never touch the terminals while the relay is powered, and if your SSR came with a plastic cover, use it. Even when the SSR is switched off, a very small amount of current will flow.

When an SSR fails, it most often fails permanently closed - leaving your load powered, and possibly creating a fire or safety hazard.

Choosing an SSR

I need to switch AC

Most AC applications will be switching 110 to 240 Volt power coming from the grid. If that's you, #Mains Voltage (110 to 240V AC)

We also cover low voltage AC applications - 28 VAC or less. #AC/DC SSRs

I need to switch DC

If you don't need to switch a lot of current - 9 Amps or less, consider our cost effective (and small!) #AC/DC SSRs.

At more than 9 Amps, you need a serious #DC SSRs

Mains Voltage (110 to 240V AC)

Identify your voltage

We sell AC SSRs for 120 VAC or 240 VAC operation. Look for this on the SSR Product pages under the Maximum Load Voltage specification. If you are unsure what voltages you could be switching in the future, the 240 VAC relays can be used to switch 120 VAC. Please note we are very conservative in how we rate relays - our 120 VAC relays are rated by the manufacturer for 240 VAC, and the 240 VAC for 380 VAC - but we strongly recommend against using them to the manufacturer rated voltage. To understand why, read the #AC SSR Protection section.

Identify your current

The current drawn by your load when turned on affects how large of an SSR you need, and how hot it will be when it runs. If you know how much current, on average, your load draws, this is what we call Average Load Current. If you don't know the average current, but you know the wattage of your device, you can calculate Average Load Current by:

Average Load Current = Wattage / Operating Voltage

Next, we need to know the current drawn by your device when it is first turned on. Many devices demand a huge inrush of current, stressing electronics. If you've ever noticed the lights dimming in the house for a second when the furnace kicks in, this is the fan motor starting up. It's very difficult to measure the Surge Current itself, so we use a multiplier based on your device type. Surge Current may also be known as inrush current.

- What other kinds of AC devices will our customers want to connect? PCs, Microwaves,

TABLE - surge current multiplier Incandescent Light Bulbs Fluorescent Light Fixtures Motors Transformers Heaters

Multiply your Average Load Current by the multiplier for your device type to calculate the Surge Current.

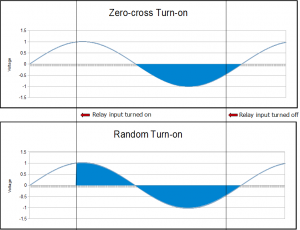

Load Type - Inductive vs. Resistive

SSRs are designed to either turn on immediately (Random Turn On), or wait until the next 'alternation' of the voltage (Zero Crossing). Zero Crossing SSRs create less electromagnetic 'noise' when they turn on, and MIGHT TBD cost more money. They are best used with resistive loads - Zero Crossing SSRs are not able to turn off some inductive loads. It's very difficult to determine which inductive loads will create problems - well beyond the scope of this document. If your load is inductive, we recommend buying the Random Turn On SSRs.

Your Load will probably be inductive if it is built around a large coil of wire - motors and transformers are typical examples. A load considered resistive may also have loops of wire - for instance, hair dryers, toasters, incandescent bulbs use twisted wire elements to generate the heat. An inductive load will have thousands of loops of wire - it's a matter of scale. There is no such thing as a perfectly resistive load - but the load has to be really inductive to cause the zero crossing SSRs to malfunction.

Another good reason to use Random Turn On SSRs for inductive loads is the coils will be wrapped around a magnetic material like iron. As the current flow generates magnetic fields, the iron is repeatedly magnetized in opposite directions. Depending on how the iron was magnetized when the power was removed, and your luck when the load is turned on, an effect called saturation can produce a huge inrush of current. Zero Crossing SSRs are more likely to turn on the load at exactly the worst time.

TABLE - specify inductive / resistive

- Incandescent Light Bulbs Resistive

- Fluorescent Light Fixtures Older units (magnetic ballast) may be inductive, newer units resistive (electronic ballast)

- Motors Inductive

- Transformers Inductive

- Heaters Resistive

- Computer / Electronics

- AC/DC power supplies (brick heavy type) Inductive

- AC/DC Power supplies (lightweight switchers) Resistive

Remember, if your load is inductive, choose a Random Turn On relay. If your load is resistive, choose a Zero Crossing relay.

Picking your AC SSR

Now that you have identified your Operating Voltage, Average and Surge Current, and your load type (inductive or resistive), you can create a short list of relays whose

- Maximum Load Voltage are greater than or equal to your operating voltage,

- Maximum Load Current are greater than or equal to your surge current, and

- Turn On Type matches what you chose for random turn on/zero crossing.

Now compare the Load with No Heatsink value for the SSRs on your list to your Average Load Current. If your Average Load Current is greater, you need a heat sink. For picking a heatsink, please go to #Picking a heatsink Consider other SSRs on your list - there may be an SSR that can handle your average load current with no heatsink.

At this point, you know the SSR you need.

Instead of simply turning the load on/off, do you want to dim it? SSRs that are able to reduce the average power to the load are called Proportional Control SSRs. Read about them here

AC SSR Protection

Your AC SSR from Phidgets comes with a circular disc with two legs. <Picture> This is a Metal Oxide Varistor (MOV) and should be installed across the load (larger) terminals of your SSR <Picture>. MOVs are the classic surge protector - an inexpensive component that absorbs high voltage spikes. High voltage spikes are caused by inductive loads when they are turned off, and also happen very often on the electrical grid, as nearby devices are operated. Even if your load is resistive, use an MOV to protect the SSR.

MOVs have a limited life span - they must be carefully chosen. If an MOV is chosen for too low of a voltage spike, it will wear out quickly. If it is chosen for too high of a voltage spike, it will not protect the SSR adequately. MOVs are not perfect devices - therefore we have chosen SSRs which can survive much higher voltage spikes than what we recommend them for. For example, this is why the AC SSRs we recommend for 120 VAC operation are rated by the manufacturer for 240 VAC. If you must operate our AC SSRs are higher voltages than we recommend, do not use the included MOV.

As MOVs wear out from use, they will become more sensitive to common voltage spikes, causing them to wear out quicker. When they entirely fail, they will become a short circuit, potentially creating a fire hazard. The MOV included with your SSR has a fuse built in which will disable the MOV when it becomes a hazard. Please consider (and avoid!) nearby flammable material when mounting your SSR.

- TMOV20RP200E

- TMOV20RP385E

Proportional Control SSR

Proportional Control Relays (often simply called "Control Relays") are SSRs you can use to control the amount of power to the load. Rather than reduce the voltage, or somehow limit the current - which would be very expensive solutions, the Proportional SSR reduces power by turning the load on/off quickly, feeding full power in short pulses. A similar technology is used for motor control, called PWM (Pulse Width Modulation).

Proportional SSRs are controlled by a variable voltage - as the voltage increases, more power is available to the load. Our PhidgetAnalog product can be used to control Proportional SSRs. We don't sell Proportional SSRs - but they can be purchased from Digikey, where they are called AC Linear Controlled SSRs.

A quick and dirty (and inexpensive!) solution for dimming with Phidgets is to use an RC Servo Motor with a PhidgetAdvancedServo to rotate the knob on a light dimmer. From software, the RC Servo Motor is rotated to an absolute position, cranking the knob as it turns. Link to Servo Motor Primer

Example circuits with AC SSRs

- Show diagram of switching 240V 1-ph load, and 240V split phase (like your stove)

Did you know?

Mains Voltage SSRs cannot switch DC. They will never turn off.

- Why do AC SSRs leak current? What is a snubber? What effect does this have on efficiency?

- What happens when an AC SSR fails? Usually it turns on permanently - make sure this doesn't cause a safety hazard. For instance, Sauna Heaters have a simple mechanical thermal shutdown to protect if control electronics fails.

- Why do AC SSRs have a minimum current rating?

- AC SSRs will take 1-2% of the power.

Home for potentially useless Zero-cross Turn-on vs. Random Turn-on

AC SSRs are designed to either have have a zero-cross turn-on or a random turn-on characteristic. The type you should choose is determined by the nature of the load you're switching. If you're switching a DC load, you can ignore this section.

Zero-cross Turn-on

An SSR with this feature will only switch on when the proper voltage is applied to the input terminals and when the output voltage is near zero. This is ideal for applications with resistive loads or systems that want to avoid sharp voltage changes.

The relay will turn off when the input voltage is close to zero and the load current is near zero.

Random Turn-on

An SSR with this feature will immediately switch on when the proper voltage is applied to the input terminals, regardless of what voltage the output terminals are at. This is ideal for applications with inductive loads, since using a zero-cross turn-on SSR with an inductive load could cause the relay to stay on indefinitely.

The relay will turn off when the input voltage is close to zero and the load current is near zero.

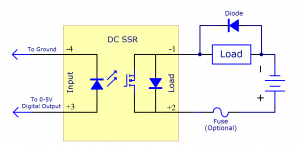

DC SSRs

- We sell DC SSRs in the Hockey Puck form factor - great for putting on heat sinks.

- Needs to be protected with a Diode across the load. Your SSR bought from Phidgets includes a diode.

- Doubling the current through a DC SSR will quadruple the heat generated. They are very efficient at smaller currents.

- important specification is the resistance - this and current set how much heat is generated.

- Steal a bunch of information from AC SSR heat sinking / power dissipation.

- Link to section about choosing wire thickness.

- Show a picture of a simple load with the diode attached.

- Describe transients in the context of DC switching.

- Make sure it's clear which way the diode is attached.

- What happens if you switch AC with a DC SSR?

Direct Current (DC)

- Why can't it switch AC?

- comes with diode to protect load (diagram)

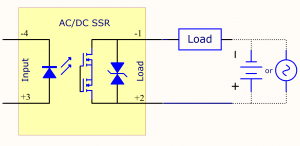

AC/DC SSRs

- To switch low voltage, low current applications in either AC or DC, a small #Versatile (AC/DC) would be ideal.

- Can switch AC (up to 28VAC) or DC (up to 40 VDC).

- Doesn't need to be protected with a diode or MOV.

- Switches up to 9 Amps.

- Effectively is two DC SSRs built back to back, so it can block AC in either direction. This is not as cost effective for switching AC, but it's able to switch lower voltage AC.

- These small SSRs can be used to isolate the digital input on a Phidget, protecting them from interference and harmful transients.

- Link digital input sections

Versatile (AC/DC)

- how is it able to switch both AC and DC?

Using heatsinks with Hockey Puck SSRs

SSRs will only achieve their promise of reliability and long life if they are kept cool. Cool is relative, of course, but a good rule of thumb is to keep the metal base of the SSR at less than 85 Celsius.

Excess heat usually comes from too much current and too little heatsinking. A lot of heat can also be generated by turning the relay on and off frequently. If your relay is being operated for brief periods of time, you may not need as large of a heatsink - provided the relay is never accidentally left on for extended periods. Unless space is a concern, it's better to err on the side of caution.

Do you actually need a heatsink? If your application is running at room temperature, and your average current is less than the Load with no Heatsink specification of your SSR, then no, you don't need a heatsink.

- Based on your knowledge of your application, do you need a heat sink?

- Check your SSR's data sheet to get an idea of the amount of heat it will be generating based on your application's load.

- If the SSR cannot be mounted on a surface that is suitable for conducting away the heat, you should use a heatsink.

- How to tell if SSR is "too hot"?

- causes of excess heat- too much current or too little heatsinking

During the discussion of the generation of heat, we can introduce the hockey puck physical form factor, and how that is relevant to heat sinks.

Phidgets includes a grey pad with our Hockey Puck form factor SSRs. You place this pad under an SSR when mounting it on a heatsink, or on large metal surfaces that can dissipate heat. The pad takes the place of thermal grease - if you are more comfortable with thermal grease, you can use it instead.

Our heat sinks include screws for mounting SSRs. <Show picture of heat sink + thermal pad + SSR>, and another picture assembled.> Use a good size screwdriver when tightening the SSR down on the heat sink.

Hooking up wires to the Hockey Puck SSR

< Need picture of wires clamped onto the SSR, with the MOV on top >

When wiring your load to the SSR, the wire is looped clockwise around the terminal, so as the screw is tightened down, it will draw the wire in tighter. We recommend using wires up to 10 AWG in size - any larger, and the screws will not have enough thread left to tighten down, and they will strip. 10 AWG wiring is conservatively rated at 30 Amps, TBD posing a problem to use SSRs rated higher than 30 AMPS. Larger wires can be attached using a wiring lug. The lug is clamped under the SSR screw, and the wire attaches to the lug. <picture of TRM6 on SSR with big wire attached>

Loose wire connections can generate a lot of heat - use a good size screwdriver when clamping down the load wires.

For the current ratings of various wires sizes, please see Page on Wire Sizes