|

Notice: This page contains information for the legacy Phidget21 Library. Phidget21 is out of support. Bugfixes may be considered on a case by case basis. Phidget21 does not support VINT Phidgets, or new USB Phidgets released after 2020. We maintain a selection of legacy devices for sale that are supported in Phidget21. We recommend that new projects be developed against the Phidget22 Library.

|

Mechanical Relay Primer: Difference between revisions

No edit summary |

|||

| Line 35: | Line 35: | ||

====Prolonging Relay Lifespan==== | ====Prolonging Relay Lifespan==== | ||

* | =====Arc Suppression ===== | ||

The main cause of failure for mechanical relays is electricity arcing across the contacts. To lengthen the lifespan of your relay, you can add various circuit elements that mitigate arcing. | |||

For DC powered applications, the most effective method of arc suppression is to place a feedback diode across the load (diagram). | |||

For AC powered applications, there are a number of options for arc suppression: | |||

* You can put a snubber across the load terminals. A snubber is a simple circuit consisting of a capacitor and resistor in series. (diagram, digikey) | |||

** Recommended values? | |||

* You can put a Metal Oxide Varistor (MOV) across the load terminals in order to protect the relay from voltage spikes. (diagram, digikey) | |||

* You can put a Transient Voltage Suppressor (TVS) such as a SIDAC (Silicon Diode for Alternating Current) to suppress contact arcing. (diagram, digikey) | |||

* How to choose which of the three above? | |||

* avoid high voltage / highly inductive loads | * avoid high voltage / highly inductive loads | ||

* avoid high frequency switching (think of switch lifetime in term of # of switches, not time) | * avoid high frequency switching (think of switch lifetime in term of # of switches, not time) | ||

Revision as of 20:02, 1 December 2011

|

|

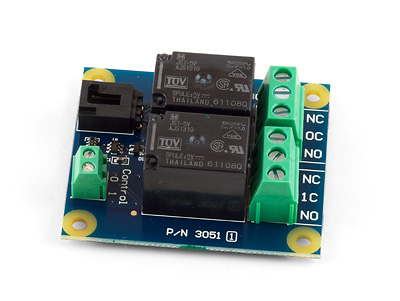

Introduction

Mechanical relays are designed to turn on or turn off the power supplied to other devices using a simple signal from a digital output. They are similar to Solid State Relays except they are less expensive, but are also less sophisticated and have a shorter lifespan. You can use them to control LEDs, heaters, appliances, and generally powered device as long as the power you're switching falls within the limits of the relay you're using.

How it works

Mechanical relays use a simple electromagnet to open or close the circuit. When current runs through the input and energizes the coil, it creates a small magnetic field which either pulls the arm of the switch away from the other contact of the switch, or pushes it down to close the switch depending on the how the switch is made.

- (add diagram)

Basic Use

Controlling a mechanical relay is as easy as turning on an LED. Any Phidgets device with a Digital Output should be able to control a mechanical relay.

Contact Bounce

As with any mechanical switch, relays are susceptible to contact bounce. This means that when the switch closes, the arm can bounce on the contact, causing the load's power to flicker slightly. This usually only matters when the application is detecting when the power signal turns on. For example, a circuit designed to increment a counter every time power is applied to its input could incorrectly interpret a bouncing switch as multiple events. Check the switch primer for information on how to deal with switch bounce. It's worth noting that Solid State Relays don't suffer from contact bounce, because the operate without using moving mechanical parts.

Arcing, Interference, and Sticking

When a mechanical relay opens or closes, and the arm of the switch is very close to the contact, the electric current can arc through the air between the contacts. This arc can cause interference with nearby electrical instruments and sensors. This arcing can heat up the contacts of the switch enough that they can eventually weld together, causing the relay to stay on permanently.

Prolonging Relay Lifespan

Arc Suppression

The main cause of failure for mechanical relays is electricity arcing across the contacts. To lengthen the lifespan of your relay, you can add various circuit elements that mitigate arcing.

For DC powered applications, the most effective method of arc suppression is to place a feedback diode across the load (diagram).

For AC powered applications, there are a number of options for arc suppression:

- You can put a snubber across the load terminals. A snubber is a simple circuit consisting of a capacitor and resistor in series. (diagram, digikey)

- Recommended values?

- You can put a Metal Oxide Varistor (MOV) across the load terminals in order to protect the relay from voltage spikes. (diagram, digikey)

- You can put a Transient Voltage Suppressor (TVS) such as a SIDAC (Silicon Diode for Alternating Current) to suppress contact arcing. (diagram, digikey)

- How to choose which of the three above?

- avoid high voltage / highly inductive loads

- avoid high frequency switching (think of switch lifetime in term of # of switches, not time)

Choosing a Relay

I need to switch AC

- mains voltage

- low voltage

I need to switch DC

- 5A or less

- greater than 5A -> look at SSRs

Types or Classes

- Switch types (SPST SPDT)

- Latching relay?

Conclusion

- Much the same as the Introduction, but using reference to supplied information to justify the statements.